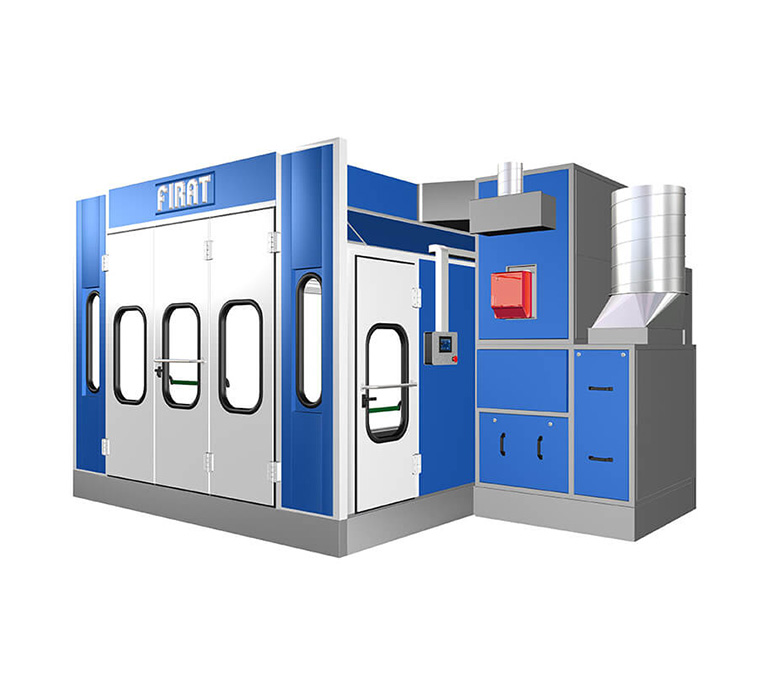

Firat FBK 7000 Spraybooth 36000 M3H

Product Description:

- Internal Dimension: 7000 x 4000 x 2650mm

- External Dimension: 7200 x 4080 x 3500mm

A Painting and Drying Spraybooth is the structure where a vehicle is painted with a spray gun. It has a low-pressure air channel where the air is removed from the facility through a filtering system.

Paint stop filters remove various dust and particles from the air. The spray booth unit is equipped with fan-motor units that can be installed on the facility floor, with an entrance ramp at the front and a metal basement to connect to the air circulation units.

Function:

The auto painting and drying operation follows strict health and safety guidelines. It conforms to TSEK which is determined by the Quality conformity certificate no. 35 -14.02/1557 of 2001. Under Law no. 132 and TSE legislation, the “Production Compliance Certificate” has been approved. Analysis conducted by TUBITAK ENERGY SYSTEMS and ENVIRONMENT RESEARCH INSTITUTE ENVIRONMENT DIVISION, stated in report no. B.02.1BAK.5.01.52.00/2015 and Project no. 51H2402, that FIRAT Auto Painting Spray Booths do not constitute any environmental pollution.

- Images are for illustration purposes only

- All preparation bays, mixing rooms, and spray booths can be customised according to your requirements. Please contact us for more information.

Product Specifications

| INTERNAL DIMENSIONS | 7000(L) x 4000(W) x 2650(H) mm | |||||||||

| EXTERNAL DIMENSIONS (Excluding Fan Units) | 7200(L) x 4080(W) x 3500(H) mm | |||||||||

| ENTRANCE DOOR | 2600 (W) x 2590 (H) mm | |||||||||

| SERVICE DOOR | 800 (W) x 2127 (H) mm | |||||||||

| LIGHTING | TOP LIGHTING | 40 x 36W | ||||||||

| LOWER LIGHTING | NO | |||||||||

| FRESH AIR AND HEATING UNITS | FAN MOTORS | 11 KW | ||||||||

| AIR FLOW | 36.000 m³/h | |||||||||

| DIESEL BURNER | 250.000 Kcal/h | |||||||||

| MAX DRYING TEMPERATURE | 60oC /80oC | |||||||||

| EXHAUST UNIT | FAN MOTORS | 11 KW | ||||||||

| AIR FLOW | 36.000 m³/h | |||||||||

| FLOOR FILTER | EU3 | |||||||||

| CEILING FILTER | EU5 | |||||||||

| METAL BASEMENT | – | |||||||||

| PLENUM | – | |||||||||

| GRATES | 2 Lines Grates , 3 Lines Closed Plates | |||||||||

| MAX WEIGHT | 500Kg / Wheel | |||||||||

| MAX. ELECTRIC POWER | 25Kw | |||||||||

| PANEL ELECTRIC VOLTAGE | POWER | 380V | ||||||||

| COMMAND | 24V | |||||||||

| DUCTING | FRESH AIR | 700 x 500 mm (2 Sets) | ||||||||

| EXHAUST | 600 x 600 mm (2 Sets) | |||||||||

| BURNER | 235 x 235 mm | |||||||||

| UNIT DIMENSIONS | (L x W x H) – DIMENSIONS mm | |||||||||

| EXHAUST UNIT DIMENSIONS | – | |||||||||

| EXCHANGER UNIT DIMENSIONS | – | |||||||||

| EXCHANGER LENGTH | – | |||||||||

| FRESH AIR UNIT DIMENSIONS | – | |||||||||

| CONTROL PANEL | – | |||||||||

| PRESSURE & TEMPERATURE CONTROL | – | |||||||||

Features

Provides auto painting and drying operation in accordance with health and security norms. Conformity to TSEK quality factor and conformity values is determined with Quality conformity certificate no. 35 -14.02/1557 of 2001. In accordance with the Law no. 132 and TSE legislation, “Production Compliance Certificate “ had been consigned. Analysis result executed by TUBITAK ENERGY SYSTEMS and ENVIRONMENT RESEARCH INSTITUTE ENVIRONMENT DIVISION, approved through the report no. B.02.1BAK.5.01.52.00/2015 and Project no. 51H2402, that FIRAT Auto Painting Spray Booths does not constitute any environment pollution.

Main Cabin

Side walls are made of galvanised 1mm steel sheets, with 40 mm glass-wool insulation. It helps to prevent heat loss and makes FIRAT spray booths much more economical and efficient. Additionally it allows for quieter operation and reduces noise pollution. In order to provide an ergonomic view and longer life, outside surface of the panels are painted with durable static powder paint.

FIRAT products have the illumination system which had been designed in order to optimise the colour control during the painting phase. FIRAT spray booths have a hanger system with rails hanged up to the ceiling, which allow to hang parts, which are being painted or drying beside the automobile. Ceiling is the section which provides the excellent air flow. The air is driven from outside, filtered (and heated in the bake phase) and blow inside the booth. Ceiling consists of sheet panels with special insulation and high performance and durable filters made of non-flammable material. There are four leaf doors at front of the booth for vehicle entrance and single door system for personal entry and exit. Door items have observation windows made of safety glass. All the doors are 55 mm deep and insulated with 55 mm glass wool.

Air Make-Up Unit

This unit supplies the filtered fresh air into the booth and throws the used air outside during painting phase. On the other hand, during drying it heats the air up to 60 °C , mix used air with fresh air in proportion of 10% (through the multi damper) and circulates it after re-heating. This recycling of the already warmed air is very effective and energy efficient. It can speed up the process and safes lots of energy.

The air is heated by a diesel burner having a capacity of 150.000 kcal/h and an exchanger made of stainless steel sheet. We can supply a direct or indirect gas burner. Start up and rising the air temperature up to 60 °C takes approximately 15 minutes, depending on outside weather conditions.

Delivery of the heated or not heated air into the booth or circulation of it is provided by two industrial type fans, each having the capacity of 18.000 m³ / h. In this unit air is delivered to the booth after filtered by a pre-filter. Additionally output air is controlled by a damper in the output air channel.

Electrical System

Electric and Command Panel

Panel in which the motors and devices in the enclosure of the proposal are operated and controlled from a central point in order to provide them to fulfil their functions. Panel is made of galvanised sheet and steel profiles, which are bump resistant, completely covered, water proof and damp proof. Panel shall include all switches and fuses necessary for motors and electrical devices, where appropriate signal lamps, thermic relay, contractor and clemencies.

Wiring

Command and control connections from electric panel to motors and other electrical devices shall be done with heatproof cables.

Electric lines shall be placed on a basis so that formation and replacement is easy. Ready to operate devices: 380 V.50 Hz. Voltage of control devices is 24 volt.